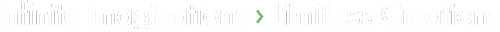

UltiMaker Factor 4 3D Printer

15% Discount Promotion

Pricing starting from

$42,032.50 $49,450.00 incl GST

Get your UltiMaker Factor 4 with 15% discount off RRP, limited time only (whilst stocks last). Feel free to call (03-9111 0104) or email us via the contact form below, and our friendly team will get back to you shortly.

Industrial-grade performance. Reliable and repeatable results |

UltiMaker Factor 4 industrial-grade 3D printer is designed to take manufacturing to new levels of efficiency and reliability. It is engineered for the development and production of process-critical tools and components. With support for engineering materials, direct drive dual extrusion, onboard print quality reporting (license subscription required), temperature-controlled build volume 330 x 240 x300 mm, and other innovative features, it delivers high levels of predictability and minimal variance - achieving a dimensional accuracy of ± 0.2 mm + ± 0.2% of feature nominal length over the full build plate. UltiMaker Factor 4 is capable of printing up to 340 °C using the HT print core. This means that you can now 3D print higher temperature-resistant, fire-retardant, and chemical-resistant composite material like UltiMaker PPS-CF that could serve as potential alternative for creating less demanding steel, aluminium and PEEK parts. Built on over a decade of dedication to openness and accessibility, the machine will support one of the widest material portfolios on the market for a variety of applications, including end use parts, functional prototyping, manufacturing tools, and small batch manufacturing of auxiliary components and spares. |

Built for the factory floor |

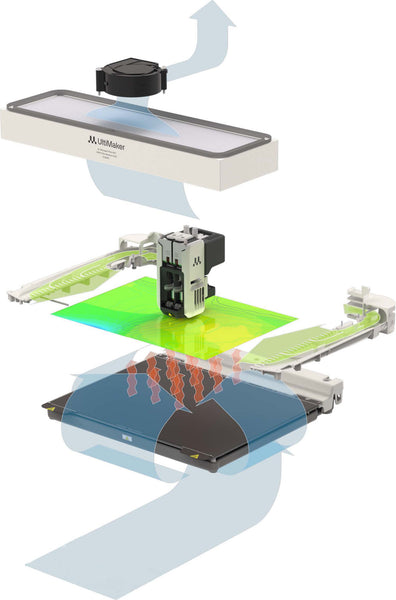

Constructed from robust steel, aluminium, and glass, Factor 4 is built for the factory floor. The printer features a triple-insulated build volume, closed loop and direct drive dual extrusion, automatic inductive bed levelling, and a PEI-coated flexible build plate, ensuring consistent production output, even on complex and challenging designs. The integrated, low moisture material handling system is climate controlled, with humidity levels kept below 15%, and holds up to six spools of filaments in their prime condition. |

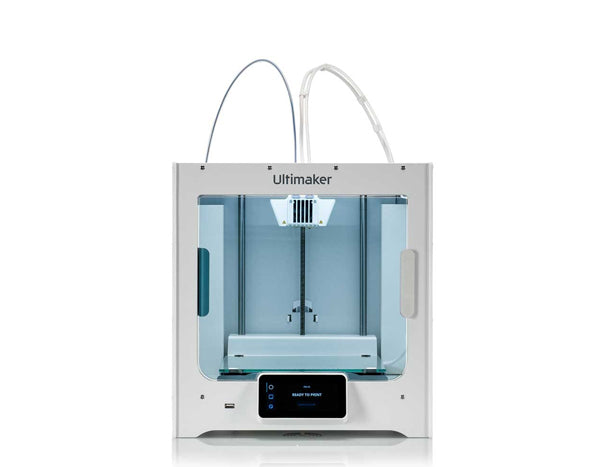

Fully redesigned extrusion train |

The combination of the all-new H-bridge gantry and direct drive extrusion print head allows high-speed movement and positional accuracy. This results in best-in-class dual material printing speeds so that you can quickly create the flexible or strong parts you need. |

|

New direct drive extrusion, high temperature 3D printingFactor 4 expands the range of high performance, industrial-grade materials, from flexible materials to high-temperature composites. 3D print flexible materials from TPU 95A down to Shore 70A (TPU 70A) reliably with Factor 4, enabling you to create flexible parts like gaskets, seals, and shock absorbers. UltiMaker Factor 4 raises the temperature up to 340 °C using the UltiMaker HT Print Core. This means that you can now 3D print higher temperature-resistant and durable materials like UltiMaker PPS-CF with more confidence. UltiMaker PPS-CF is a semi-crystalline thermoplastic material, reinforced with carbon fiber. The material has a temperature resistance greater than 230°C, is flame retardant, and highly chemical resistant. It provides a high-performing alternative to steel or aluminium for less-demanding parts, enabling users to unlock new industrial applications. |

Success with every 3D print |

The UltiMaker Factor 4 has been thoroughly tested to ensure it achieves a print completion success rate of over 95% (print completion success rate tested using UltiMaker PLA, Tough PLA, PETG, PET CF, and PPS CF). This is made possible by its PEI-coated flexible built plate, allowing for excellent adhesion. And its automatic inductive bed leveling to ensure a perfect first layer for every print. |

|

New High Temperature Print CoreUltiMaker Factor 4 raises the temperature up to 340 °C using the new HT print core. This means that you can now 3D print higher temperature-resistant and durable materials with more confidence, such as the new UltiMaker PPS-CF material. The temperature within the fully enclosed Factor 4 build volume is also controlled up to 70 °C, with a heated bed up to 120 °C, ensuring optimal material-specific processing conditions and consistent part quality wherever the 3D printer is located. |

|

Exceptional part performance for industrial 3D printing applicationsUltiMaker PPS-CF, a high-temperature composite material for Factor 4 with HT Print Core, offers a robust alternative to steel or aluminium when creating less-demanding parts. This semi-crystalline thermoplastic, reinforced with 10% carbon fibre, boasts a heat deflection temperature of more than 230 °C after printing. It is also highly chemical resistant and resists solvent below 200 °C. And and it meets the UL94 V0 standard for flame retardancy. Its properties also allow it to potentially replace PEEK – offering a more cost-effective, more reliable, and easier 3D printing experience, and – thanks to soluble support compatibility – full design freedom. This new UtliMaker material is opening up new categories of 3D printing applications. |

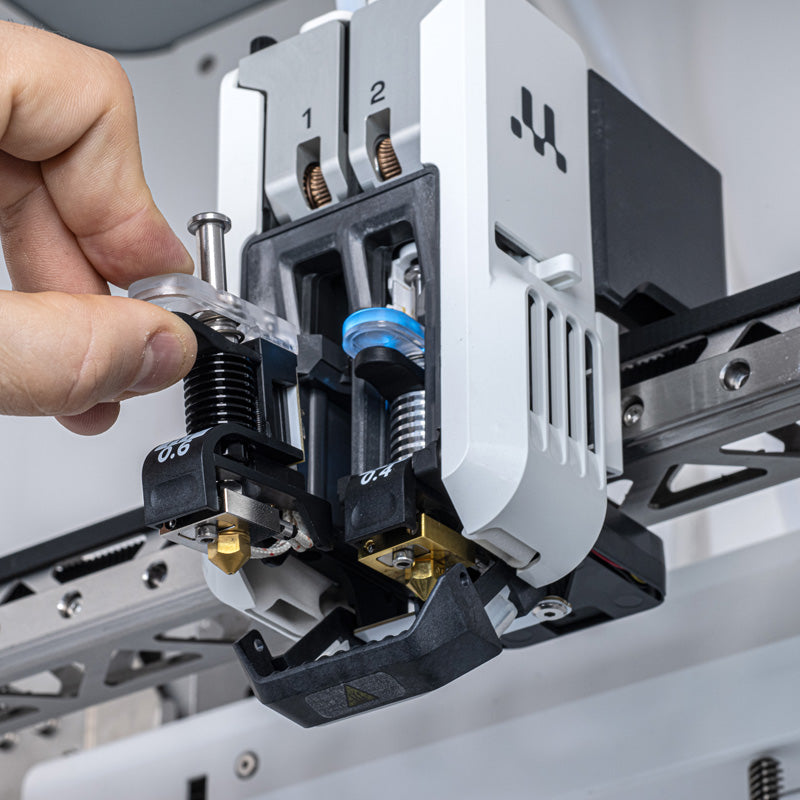

Hassle-free material handling |

A new, integrated, automatic material handling system reliably manages your filament spools so you don’t have to. The internal chamber is kept at less than 15 % RH, so you can keep up to 6 kilograms of filament in perfect condition for back-to-back print jobs. It features an automatic material change capability, which seamlessly switches between filament spools, eliminating downtime and ensuring uninterrupted printing, for those printing a single part that may require several days or multiple spools. |

|

Actively temperature controlled build volumeThe UltiMaker Factor 4's spacious triple-insulated build chamber allows you to utilise every millimetre of the build plate with direct drive dual extrusion. This means that you can now 3D print higher temperature-resistant and durable materials with more confidence. The temperature within the fully enclosed build volume is also controlled up to 70 °C, with a heated bed up to 120 °C, ensuring optimal material-specific processing conditions and consistent part quality wherever the 3D printer is located. |

|

|

Modularity at your serviceUltiMaker Factor 4 was designed to be modular. This means less production downtime in the event that a part of the printer needs servicing. Faulty component can be quickly swapped out for a functional one to get you up and running again as quickly as possible. |

7-inch interactive touchscreenUltiMaker Factor 4's larger 7-inch interactive touchscreen shows more real-time process data. |

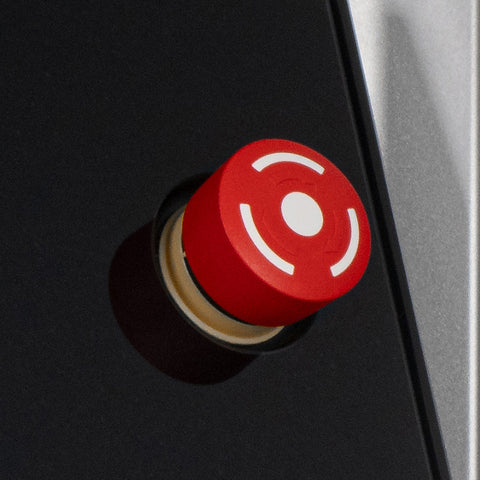

Emergency stop buttonAn Emergency STOP button ensures safe operation, should there be a need to immediately halt printing. |

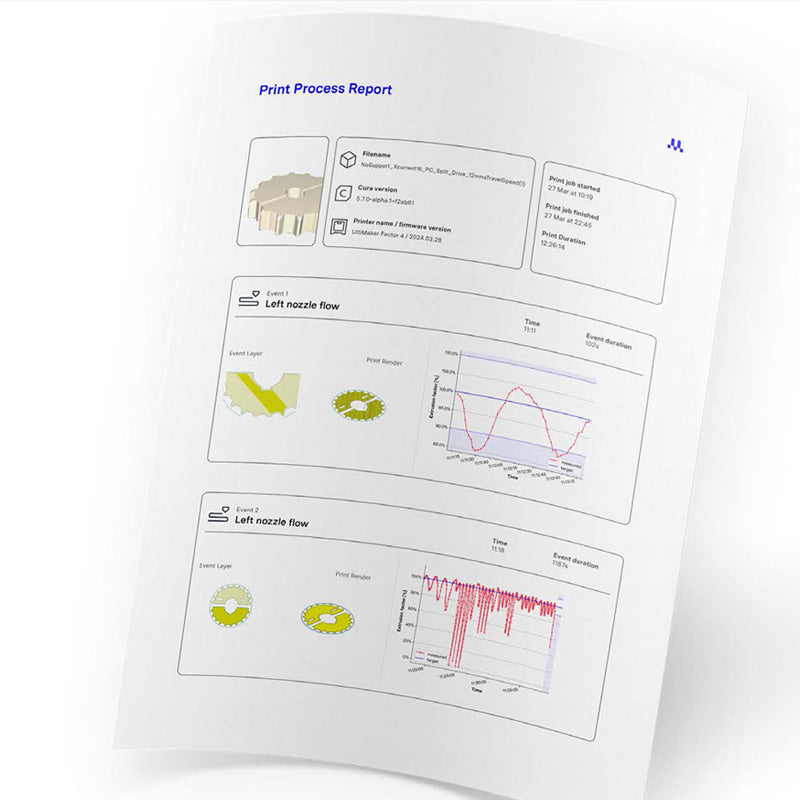

Onboard structural integrity validationSensors in the print head, build chamber, and material loading system, allow for in-depth print process reporting (license subscription required) to verify and validate part quality. |

Integrated HEPA filterIndependently tested to remove up to 95% of ultrafine particles to increase air quality peace of mind. The fully enclosed build chamber also boosts print quality. |

Regular updates and fast ROI |

Regular updates ensure that your Factor 4 will evolve over time – far beyond the estimated 12 to 18 months it will take to achieve return on investment. With dual onboard processors, there is plenty of computing headroom for planned and even unplanned future updates. |